Accurate alignment is crucial in any mechanical setup. Even slight misalignment can cause vibration, friction, and premature wear. Machinery alignment shims provide precise spacing between mounting points, allowing equipment to run smoothly and efficiently.

Why Alignment Is Critical

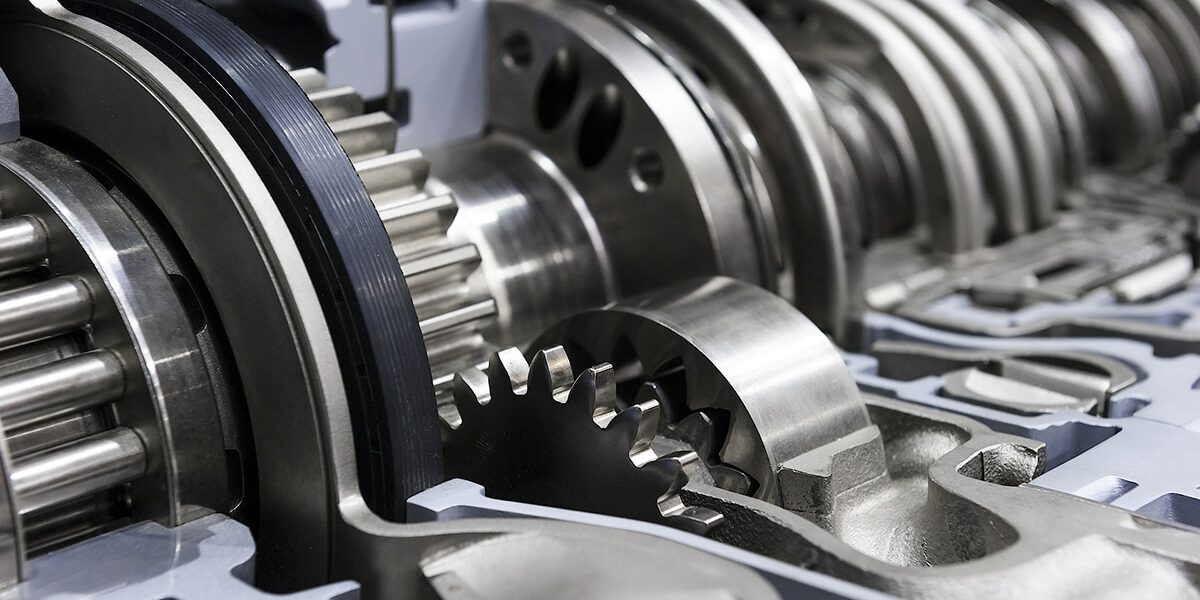

When rotating machinery, motors, pumps, compressors or gearboxes aren’t perfectly aligned, energy transfers unevenly through couplings. This imbalance creates vibration, increases power consumption, and shortens bearing life. Correct alignment ensures the load is evenly distributed, improving reliability and performance.

How Shims Achieve Precision

Shims are thin, calibrated layers placed beneath machine feet to make fine height adjustments. By stacking or swapping these layers, technicians can align shafts and bases with micron-level accuracy.

They are essential during installation, maintenance and re-assembly because they:

- Compensate for uneven foundations or settling.

- Maintain precise alignment after servicing.

- Reduce vibration and noise.

Prevent seal and bearing damage.

Types of Alignment Shims

Choosing the right shim depends on the operating environment and material requirements:

| Material | Typical Use | Key Advantages |

|---|---|---|

| Stainless steel | Heavy-duty or corrosive environments | Strength and corrosion resistance |

| Brass / copper | Electrical or softer contact applications | Conductivity and malleability |

| Plastic | Lightweight or non-magnetic assemblies | Non-conductive and easy to handle |

Thicknesses typically range from 0.05 mm to 1 mm, giving maintenance teams precise control over machine level and height.

Long-Term Benefits of Proper Shimming

- Extends machinery life by reducing stress and vibration.

- Decreases maintenance frequency and downtime.

- Improves operational efficiency and energy use.

- Enhances workplace safety through stable installations.

A small investment in correct shimming can prevent thousands of dollars in lost productivity or repair costs.

Maintaining Alignment Over Time

Temperature changes, foundation movement and vibration can slowly shift machine positions. Periodic alignment checks and replacing worn or corroded shims help maintain long-term precision.

Technicians often keep a variety of materials and thicknesses on hand to perform quick corrections during scheduled maintenance.

Final Thoughts

Whether you’re aligning a motor, gearbox, or industrial pump, quality shims play a vital role in machinery reliability. By ensuring precise, stable alignment, they protect equipment, reduce costs, and keep production running efficiently.

Frequently Asked Questions

Machinery alignment shims are thin, precision-cut layers used to adjust and stabilise heavy equipment during installation. They help correct uneven surfaces, ensure proper shaft alignment, and reduce vibration that can lead to mechanical wear.

Shims should be inspected during every scheduled maintenance cycle or whenever vibration analysis shows imbalance. Over time, thermal changes or foundation movement can alter alignment, so periodic checks prevent costly breakdowns.

Yes. In certain applications, technicians may combine materials (for example, stainless steel and plastic) to achieve both strength and non-conductive properties. However, consistency in material type across load points is recommended to maintain uniform compression and performance.

Ordering Stainless Steel Shim Kits Is Simple

1. Get in Touch

Tell us the specifications and quantities of the shims you require.

2. Receive a Quote

We’ll promptly provide a competitive price tailored to your order.

3. Delivery or Pickup

Choose shipping anywhere in Australia, or collect your order from our head office.