When you’re aligning precast concrete panels, installing doors or levelling machinery, precision is key. Shims provide that precision. But with different types available, how do you decide between metal shims and plastic packers or shims?

In this guide, we’ll break down the key differences, benefits and best uses of each option. Whether you’re managing a large industrial build or commercial fit-outs, choosing the right material can save time, money and rework.

What Are Shims Used For?

Shims fill gaps, provide spacing and maintain alignment in construction and engineering. They’re used in:

-

- Tilt-up concrete panel installation

- Window and door frame alignment

- Equipment and machine levelling

- Structural corrections

- Precast and modular building setups

In short, they help everything sit exactly where it should, safely and securely.

Metal vs Plastic Shims

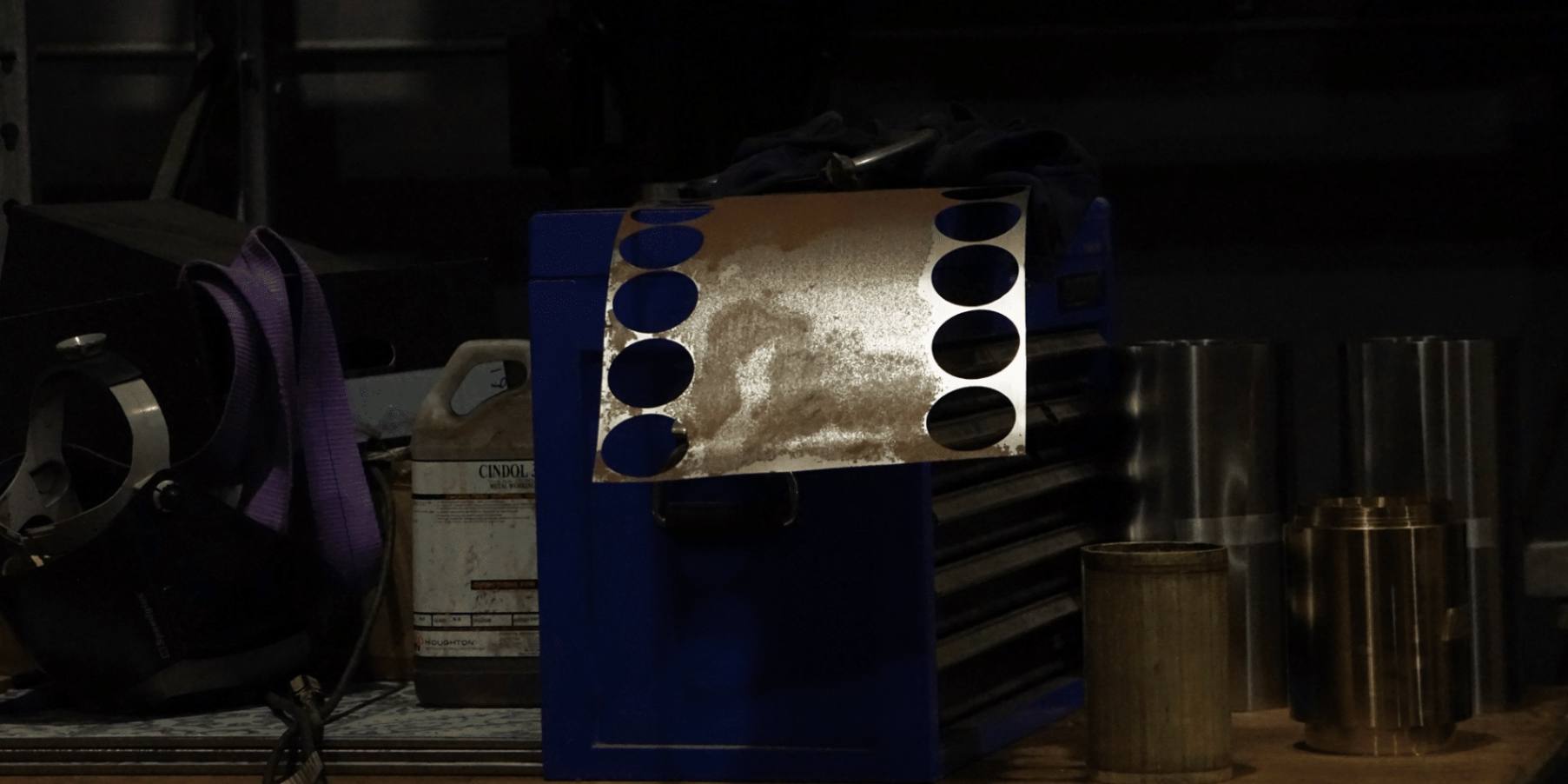

Metal Shims

Best for: Heavy-duty, high-precision or load-bearing applications

Typical Uses:

-

- Machinery alignment

- Automotive and aerospace components

- Structural steelwork

- Industrial equipment supports

Benefits:

-

- High strength under load

- Long-term dimensional stability

- Can be precision-cut to suit exact tolerances

- Resistant to deformation under pressure

Limitations:

-

- Prone to corrosion if untreated

- More effort required for on-site adjustment

- Higher material and fabrication cost

- Not as flexible for quick changes

Need custom-made metal shims? Call us on 02 4646 1166 for expert advice.

Plastic Shims

Best for: General construction, residential and non-structural applications

Typical Uses:

-

- Window and door installations

- Cabinetry and furniture assembly

- Light-duty levelling jobs

- Precast construction projects

Benefits:

-

- Lightweight and easy to handle

- Resistant to water, rot and corrosion

- Flexible, can be cut, stacked, drilled or nailed

- Cost-effective and available in bulk

- UV-stable plastic options available for long-term exposure

Limitations:

-

- Not suitable for high-load or critical support points

Can deform over time under sustained pressure

Lower temperature and chemical resistance compared to metals

- Not suitable for high-load or critical support points

Which Shim is Right for the Job

There’s no one-size-fits-all solution. The right shim for your project depends on load requirements, environmental exposure (moisture or UV), precision needed, installation method and budget or timeframe. Plastic shims are often used for large volumes and faster installs, while metal shims are better suited to applications where strength and long-term durability is critical.

Why Choose PP Shim?

At PP Shim, we supply reliable shim solutions for commercial, civil and industrial use across Australia. Whether you’re working on precast panel installation, heavy equipment levelling or structural framing, our products are built to withstand tough site conditions.

Trusted by builders, engineers and contractors, our shims are manufactured to tight tolerances and high standards, with a wide range of sizes, thicknesses and materials. We also offer fast national delivery and bulk supply options.

Contact us today to speak with a shim specialist.

Metal & Plastic Shims FAQs

Are Plastic Shims Strong Enough for Commercial Jobs?

Yes, when used within their load capacity. PP Shim supply load-rated plastic shims that are widely used in commercial builds, especially for non-structural framing, glazing and fit-out work.

Do Metal Shims Rust?

Some metals do, but PP Shim offer rust-resistant options such as stainless steel and treated brass. These are ideal for long-term, exposed or high-pressure applications.

Can I Use Plastic and Metal Shims Together?

No, it’s not recommended as the materials behave differently under load and temperature. We suggest using one type per application for consistent performance.

Ordering Metal & Plastic Shims is Simple

1. Get in Touch

Tell us the specifications and quantities of the shims you require.

2. Receive a Quote

We’ll promptly provide a competitive price tailored to your order.

3. Delivery or Pickup

Choose shipping anywhere in Australia, or collect your order from our head office.